16/8/2011

Mời các bạn đọc vài đoạn trong trang web của nhà cung cấp dưới đây:

Nguồn:

Trong thực tế ngành sản xuất cao su kỹ thuật tại Việt nam hiện nay đang sử dụng rất nhiều cao su silicone với nhiều mã hàng khá đa dạng. Cao su silicone có thể giải đáp các bài toán khi sản xuất các chi tiết cao su dùng ở vị trí nhiệt độ cao, môi trường tiếp xúc thực phẩm, thậm chí trong điều kiện có dung môi khắc nghiệt.....Người ta có thể nhớ đến cao su silicone trong nhiều trường hợp khác, mà các loại cao su tổng hợp khác chưa theo kịp.

Vì vậy, silicone là đối tượng cao su tổng hợp mà các bạn cần tìm nhiều nguồn thông tin khác nhau để phong phú thêm sự lựa chọn khi đối mặt với các sản phẩm cao su kỹ thuật.

Mời các bạn đọc vài đoạn trong trang web của nhà cung cấp dưới đây:

.......

Silicone Rubber (SiR)

Silicone Rubber

Silicone rubber is the most commonly used synthetic rubber or polymer. This rubber has similar bond structure as found in glass, sand and quartz. Silicone rubber is composed of silicone- which is itself a polymer- together with hydrogen, carbon, and oxygen. This is a unique synthetic elastomer which is made from a cross-linked polymer that is reinforced with silica. The characteristic of silicone rubber is such that it provides the perfect balance of mechanical and chemical properties that is required in today's most demanding industrial rubber applications.

Properties of Silicone Rubber

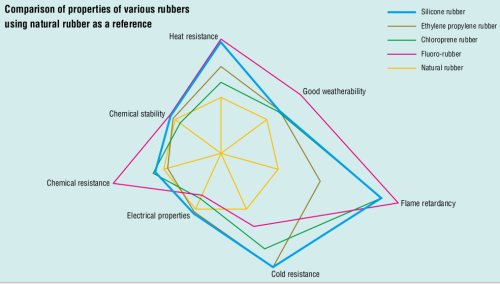

All types of silicone rubber compounds possess characteristics of both inorganic and organic materials. Due to the versatile properties of silicone rubber, it offers a number of advantages that are not found in other rubbers. Silicone rubbers have fine electrical properties, good chemical stability, flame retardancy, and excellent resistance to heat and cold.

Properties of Silicone Rubber

- Silicone rubber has higher heat resistance and chemical stability that help it in providing better electrical insulation.

- It has high elasticity and compressibility as well as excellent resistance to cold temperatures.

- Silicone rubber has resistnace to wide temperature range. It offers excellent resistance to extreme temperatures, the range of which can be from minus 100°F to plus 500°F. This rubber can be used indefinitely at 150°C that doesn't lead to any change in the properties of silicone rubber. It can withstand the temperature of 200°C for 10,000 hours or more. Some of the silicone rubbers can even withstand heat of 350°C for short periods.

- Silicone rubber has outstanding oil resistance at high temperatures. From among other common types of synthetic rubbers, nitrile rubber and chloroprene rubber have somewhat higher oil resistance at temperatures lower than 100°C but at higher temperatures, silicone rubber is superior to all other rubber types.........

|

| Bi từ cao su silicone |

- Silicone rubber has exceptional weather resistance. Ozone created by corona discharge does not deteriorate silicone rubber. Thus, silicone rubber can be exposed to wind, rain and UV rays for longer periods without any change in its physical properties.

- The tensile strength, tear strength, elongation and compression set of silicone rubber are far superior to conventional rubbers. The tear strength of silicone rubber is usually around 9.8 kN/m. Certain high-strength types of silicone rubbers also come with tear strength between 29.4 kN/m and 49.0 kN/m, achieved through polymer modification and/or judicious selection of fillers and crosslinkers.

- Thermal conductivity of silicone rubber is higher than most of the other rubbers. Silicone rubber with high thermal conductivity are used to make products like thermal interface sheets and heating rollers.

- Silicone rubber has excellent moisture and steam resistance. It can be immersed in cold, warm or boiling water for longer periods with water absorption of about 1%. This doesn't affect its mechanical strength or electrical properties. When it comes in contact with steam under ordinary pressure, there is no deterioration of silicone rubber. However, high pressure steam at temperatures above 150°C can cause breakdown of the siloxane polymer and a decline in the properties of the rubber.

- It is metal detectable.

- It glows in the dark.

- Silicone rubber is also electrically conductive.

- Apart from being resistant to oil, silicone rubber is also resistant to chemical, acid and gas.

- Silicone rubber is flame retardant and has the property of low smoke emission.

........

Silicone Rubber Applications

- This rubber can be extruded into tubes, strips, solid cord or any custom profiles.

- Silicone Rubber can also be moulded into custom designs and shapes.

- This form of synthetic rubber is available for making molds that are poured, brushed or sprayed on to a model.

- Suitable for casting low melt metal alloys like lead, tin, pewter.

- Also used in the production casting of resins.

Advantages of Silicone Rubber

Due to the physical, mechanical and thermal properties of silicon rubber, its advantages are many.

- High and low temperature stability

- Inertness, that is no taste or smell

- Translucent and easy to color

- Wide hardness range

- Chemical resistance

- Weatherability

- Sealing performance

- Electrical properties

- Compression set resistance

Disadvantages of Silicone Rubber

Although silicone rubber has many advantages to its many properties, there are certain disadvantages of silicone rubber too.

- Silicone rubber is generally high in cost.

- It is sensitive to substances like sulfur clay that may prevent the silicone from curing which is known as cure inhibition.

- Silicone rubber is usually very thick, having high viscosity.

- It must be vacuum degassed before pouring to minimize bubble entrapment.

Forms of Silicone Rubber

Silicone rubber is available in the following forms:

|

| Một sản phẩm cao su từ silicone thực phẩm |

- Compounds: These are ready to use materials which can be pigmented and catalyzed for your processing equipment and end application.

- Bases: These silicone polymers contain a reinforcing filler. The bases can be further compounded with additives and pigments that produce a compound which meet your color and other fabrication needs.

- Liquid silicone rubber (LSR): This rubber system can be pumped into a suitable injection molding machine which then can be heat cured to produce molded rubber parts.

- Fluorosilicone rubber compounds and bases: They maintain many key properties of silicone, but also has other characteristics of superior chemical, fuel, and oil resistance.........

Nguồn: